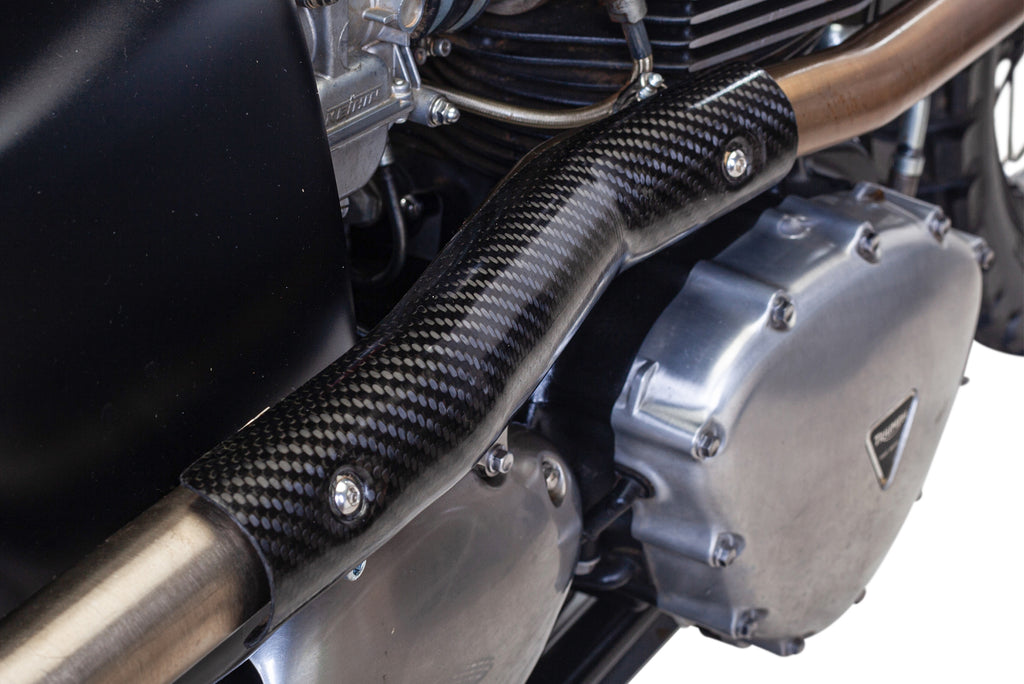

Base Model: 2011 Triumph Thruxton 900

Started from our previous Thruxton 900 EFI build, Cafe Racer Deux, we've started by switching the controls to Bonneville foot controls then the wheels to Scrambler 19/17" wheels then the rest of the bike was done up with bolt-on components

Performance Upgrades:

Handlebar Upgrades:

Scrambler Handlebar Kit

Accessories Upgrades:

Progressive 970 Shocks

Retro Sprocket

DID 525VX Gold Chain

Tires Upgrades:

Additional Custom Work

Custom Paint work by Anaheim Rod & Custom

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.